Overview of PFA Tubes

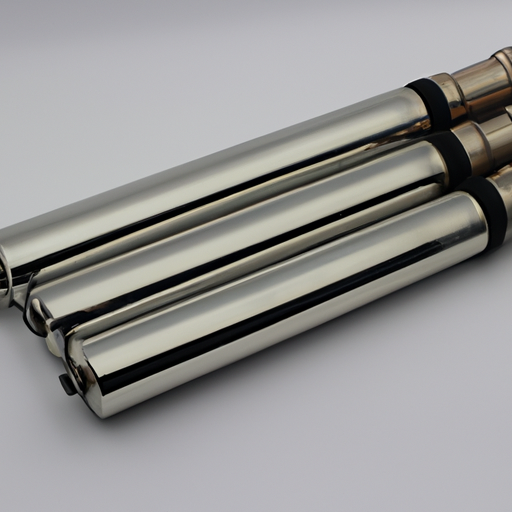

PFA (Perfluoroalkoxy) tubes are advanced fluoropolymer tubes recognized for their superior chemical resistance, thermal stability, and electrical insulation capabilities. These tubes are extensively utilized across various sectors, including electronics, chemical processing, and pharmaceuticals. The integration of PFA with materials such as silicone resin and fiberglass significantly boosts the mechanical strength and thermal performance of the tubes, making them ideal for rigorous applications.

Core Functional Technologies of PFA Tubes

1. Chemical Resistance: PFA tubes are highly resistant to a broad spectrum of chemicals, including acids, bases, and solvents. This characteristic makes them particularly suitable for use in corrosive environments, ensuring longevity and reliability.

2. Thermal Stability: PFA can endure high temperatures (up to 260°C or 500°F) without compromising its integrity, making it appropriate for applications involving high-temperature processes.

3. Electrical Insulation: With excellent dielectric properties, PFA serves as an effective insulator for electrical applications. It is commonly employed in high-voltage environments, such as the SB-SGS-12 1.2KV silicone resin fiberglass tube.

4. Low Friction and Non-Stick Properties: The non-stick surface of PFA minimizes friction, making it ideal for applications where smooth material flow is essential.

5. Flexibility and Durability: PFA tubes are both flexible and durable, allowing for various configurations without the risk of cracking or breaking, which is crucial in dynamic environments.

Application Development Cases

| 1. Electrical Insulation in High-Voltage Applications | |

| 2. Chemical Processing | |

| 3. Pharmaceutical Manufacturing | |

| 4. Food and Beverage Industry | |

| 5. Semiconductor Manufacturing |

Conclusion

PFA tubes, especially when combined with silicone resin and fiberglass, provide a multitude of functional advantages that make them suitable for various high-performance applications. Their exceptional chemical resistance, thermal stability, and electrical insulation properties are essential in industries such as electronics, pharmaceuticals, and chemical processing. The development cases presented illustrate the effectiveness of PFA tubes in enhancing operational efficiency, safety, and product quality across diverse sectors, underscoring their value in modern industrial applications.