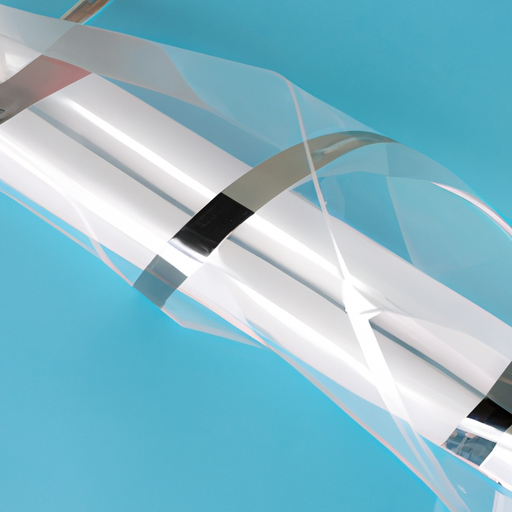

Application Development in Double Layer Acrylic Fiberglass Sleeving for SB-PVC: Key Technologies and Success Stories

Double Layer Acrylic Fiberglass Sleeving for SB-PVC (Styrene-Butadiene Polyvinyl Chloride) is a specialized material that has gained traction in various industries due to its unique properties and capabilities. This document outlines the key technologies involved in its development and highlights several success stories that demonstrate its effectiveness in real-world applications.

Key Technologies

| 1. Material Composition and Properties | |

| 2. Manufacturing Techniques | |

| 3. Testing and Quality Assurance | |

| 4. Customization and Design | |

| 1. Automotive Industry | |

| 2. Aerospace Applications | |

| 3. Industrial Equipment | |

| 4. Consumer Electronics | |

| 5. Renewable Energy |

Success Stories

Conclusion

The development of applications using Double Layer Acrylic Fiberglass Sleeving for SB-PVC exemplifies the synergy between advanced materials science and engineering. By leveraging key technologies in material composition, manufacturing, testing, and customization, industries can achieve significant improvements in performance, safety, and reliability. The success stories across various sectors underscore the versatility and effectiveness of this specialized sleeving in meeting the demands of modern applications, paving the way for continued innovation and growth in its use.