Model Number:SB-SGE-E

Working temperature: -60~240ºC

Short time peaks at 300ºC

Flame Retardant: VW-1

Directional extensibility: ≥20%

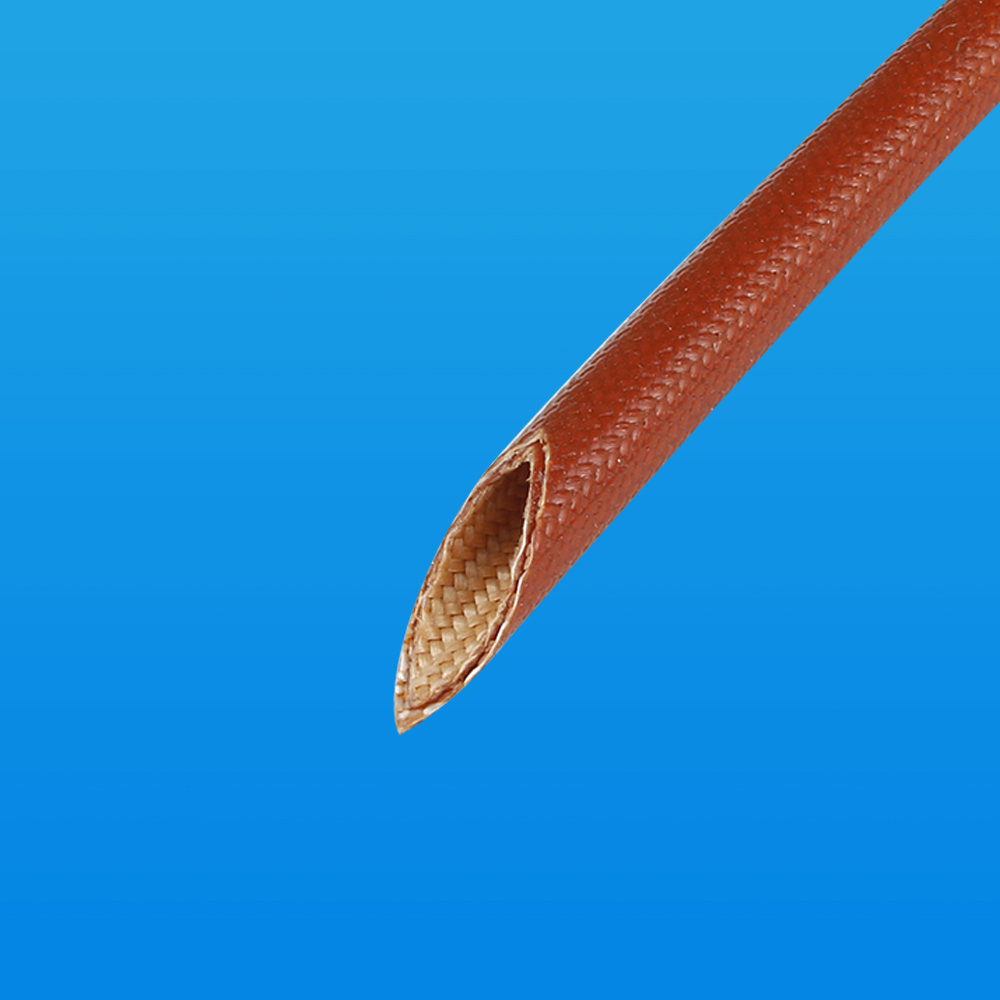

Structure

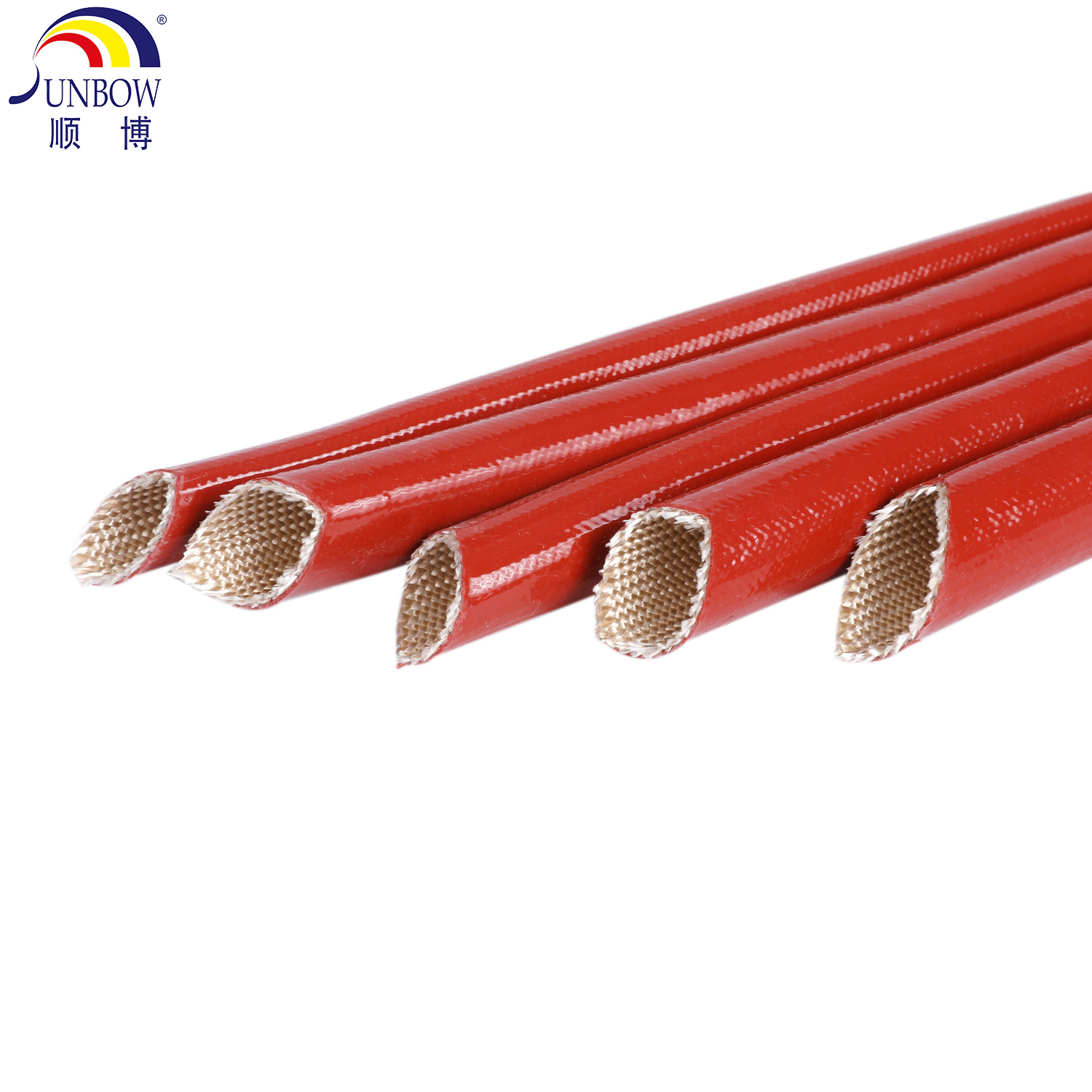

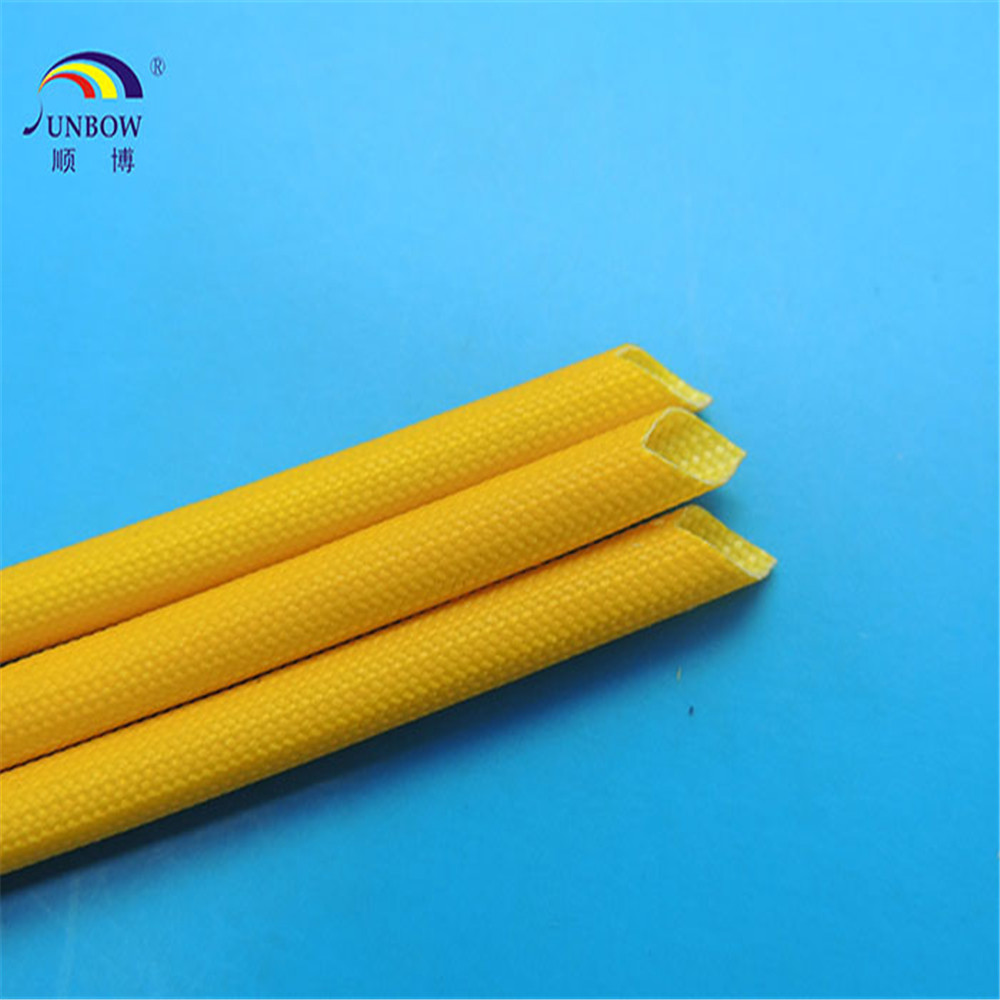

It is braided by non-alkali fiberglass, then extruded with silicone rubber and treated in high temperature.

Characteristics

![]() Flammability: self-extinguishing, wear resistance, tear resistance, good compatibility with same class impregnation varnishes, good mechanical resistance, very flexible.

Flammability: self-extinguishing, wear resistance, tear resistance, good compatibility with same class impregnation varnishes, good mechanical resistance, very flexible.

Usage

It is widely used in coil and winding industry (coils, motors, generators, transformers…); lighting, fixtures; transportation (mass transit, rail cars, locomotives…); commercial cookware (fryers, rotisseries, steamers…); heating and cooling; custom car markets and heavy truck market; and in many other industrial fields.

Specification

Item | Test Conditions | Performance |

Voltage resistance after heating | UL1441: 265℃/48 hours | Take it out and test it at room temperature. Its average voltage value is not less than half of the destruction voltage value before aging. |

Anti-aging properties | UL1441: 7days 250℃ 60 days 235℃ | After taking it out and placing it at room temperature, there is no cracking or peeling off on the surface of the product. |

Low temperature test | UL1441: -70℃/1 hour | Take out the product and place it at room temperature; wrap 6 circles with a measuring rod with the nominal diameter of the product, the product has no cracking and coating peeling off. |

Combustion test | UL1441: VW-1 UL1441:Horizontal combustion | Put the product in the test box, aim the blue flame at the marked combustion test point; burn for 15 seconds, move away for 15 seconds, and so on for 60 seconds; each time the flame leaves, it will self-extinguish within 15 seconds. |

Corrosion resistance | 0#, 93# fuel oil/1 hour S100 solvent/1 hour -50 antifreeze/1 hour Household detergent/1 hour | Pass |

Dimension

Inside Diameter | Wall thickness (mm) | Standard package (m/roll) | ||

Nominal(mm) | Tolerance(mm) | SB-SGS-E (4KV) | SB-SGS-E(7KV) | |

0.5-1.0 | +0.2, -0.1 | 0.20-0.50 | 0.40-0.80 | 400 |

1.5-4.0 | +0.3, -0.1 | 0.30-0.60 | 0.50-0.80 | 200 |

4.5-5.0 | +0.3, -0.1 | 0.40-0.75 | 0.60-1.05 | 200 |

6.0-8.0 | +0.3, -0.1 | 0.40-0.75 | 0.80-1.15 | 100 |

9.0-10.0 | +0.3, -0.1 | 0.45-1.00 | 0.90-1.40 | 100 |

11.0-14.0 | +0.3, -0.1 | 0.50-1.00 | 0.90-1.50 | 50 |

15.0-20.0 | +0.3, -0.1 | 0.60-1.20 | 1.00-1.60 | 50 |

22.0-25.0 | +0.3, -0.1 | 0.90-1.20 | 1.10-1.90 | 25 |

26.0-30.0 | +0.3, -0.1 | 1.00-1.40 | 1.20-2.00 | 25 |

32.0-40.0 | +1.0, -1.0 | 1.00-1.60 | 1.20-2.10 | 20 |

Package: Packing by rolls or cut upon request.

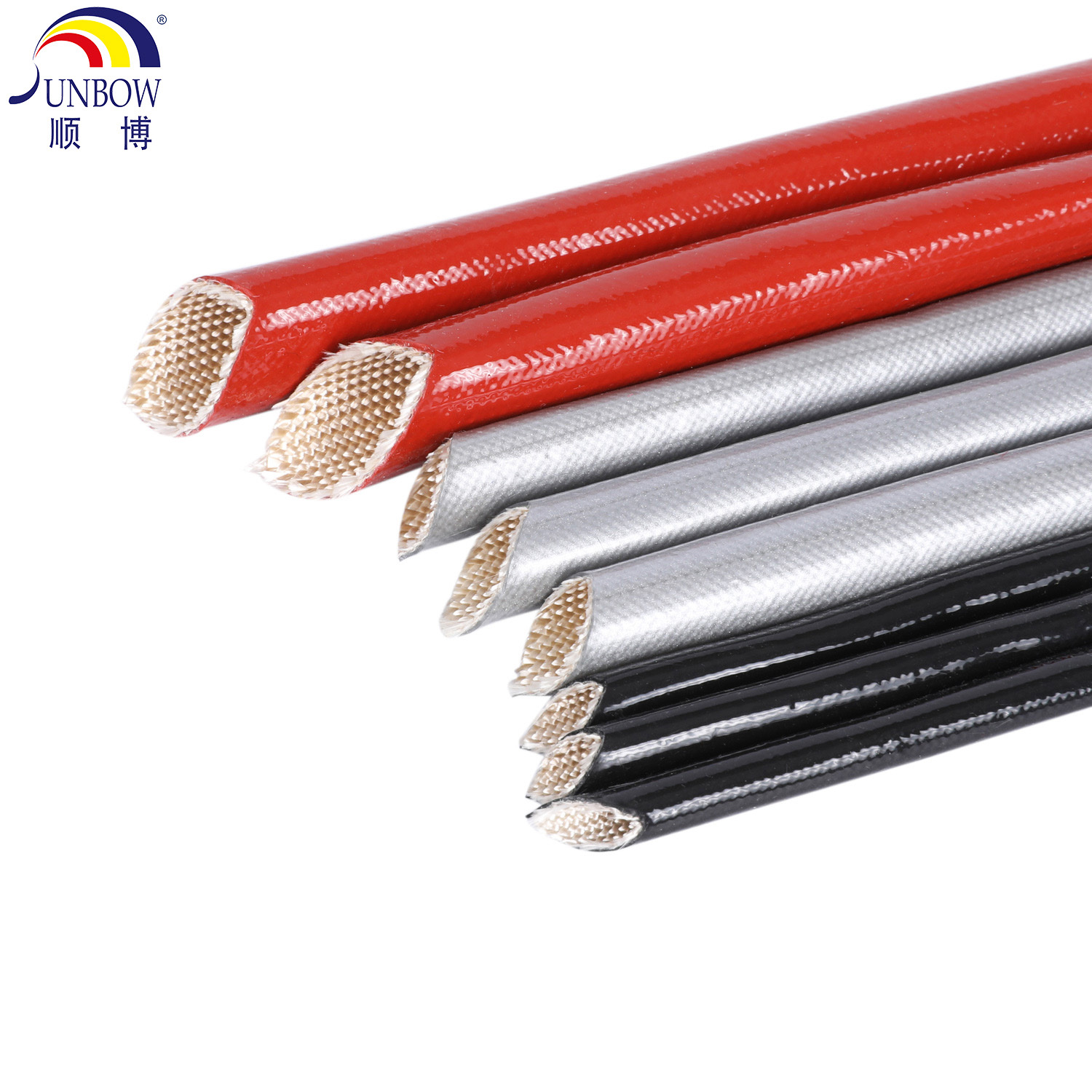

Color: Standard color is brick red, other color available upon request. The colors of braided can be customized.