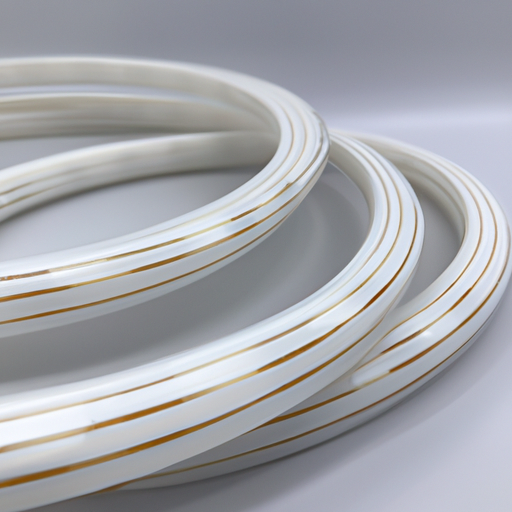

Application Development in PTFE / FEP / PFA / PVDF Tube for SB-AGSD Double Layer Acrylic Fiberglass Sleeving

The integration of PTFE (Polytetrafluoroethylene), FEP (Fluorinated Ethylene Propylene), PFA (Perfluoroalkoxy), and PVDF (Polyvinylidene Fluoride) tubes with SB-AGSD (Silicone-Based Anti-Glare Surface Design) double-layer acrylic fiberglass sleeving represents a significant advancement in material science, particularly in applications requiring high performance under challenging conditions. Below is a detailed exploration of the key technologies involved and notable success stories that highlight the effectiveness of these materials.

Key Technologies

| 1. Material Properties | |

| 2. Coating and Surface Treatment | |

| 3. Composite Materials | |

| 4. Manufacturing Techniques | |

| 5. Testing and Quality Assurance | |

| 1. Medical Device Applications | |

| 2. Chemical Processing | |

| 3. Aerospace and Automotive | |

| 4. Electronics | |

| 5. Food and Beverage |

Success Stories

Conclusion

The integration of PTFE, FEP, PFA, and PVDF tubes with SB-AGSD double-layer acrylic fiberglass sleeving represents a significant advancement in material science and engineering. This combination leads to enhanced performance in various applications, particularly in industries where chemical resistance, temperature stability, and anti-glare properties are critical. As technology continues to evolve, further innovations in this area are expected to yield even more successful applications, driving improvements in safety, efficiency, and product integrity across multiple sectors.